Innovations in the footwear industry are taking longer strides now than maybe a year ago. Today, the limits of exploration are not just confined to style but material has become the new journey worth embarking on. After recyclable materials and biodegradable options – adidas has pioneered a new textile innovation that could make shoe uppers lightweight and stronger.

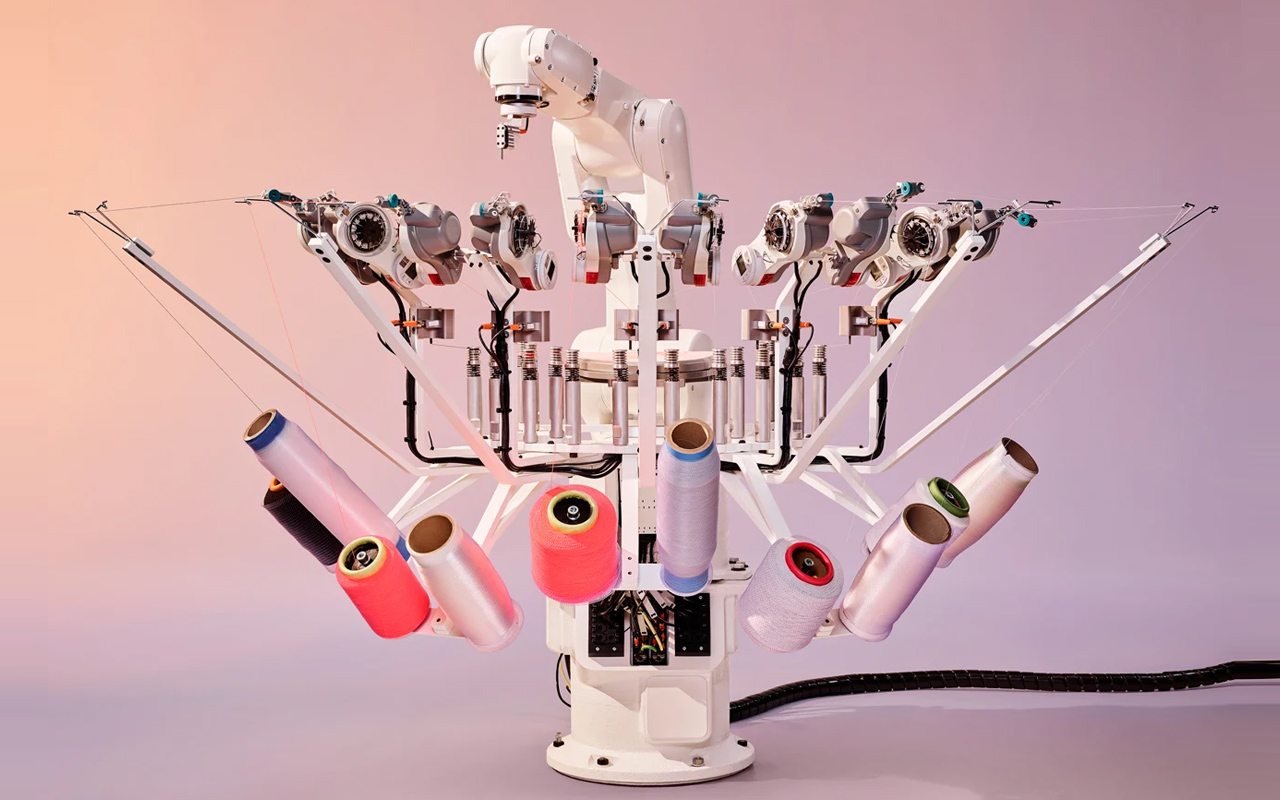

It’s called the STRUNG, and according to adidas is first textile and creation process that allows the brand’s future real engineers to feed an individual’s data [foot movement] to a custom-built robot. They can then make precision placement of treads in the required direction and have the robot weave an outstanding, lightweight shoe upper that provides a precise, flexible, and breathable fit.

Futurecraft.STRUNG

We’re seeing the Strung for the first time, but it has already stretched outside of the lab walls. The Futurecraft.Strung is first proof-of-concept shoe with upper weaved across 3D printed midsole by a robot. adidas bills this as the first “entirely data driven footwear” for specific athlete’s requirement.

This iteration of the Futurecraft.Strung is created for runners. The first marketable version – if things pan out as expected – is likely to be available by the end of next year or in early 2022.

The thread tech

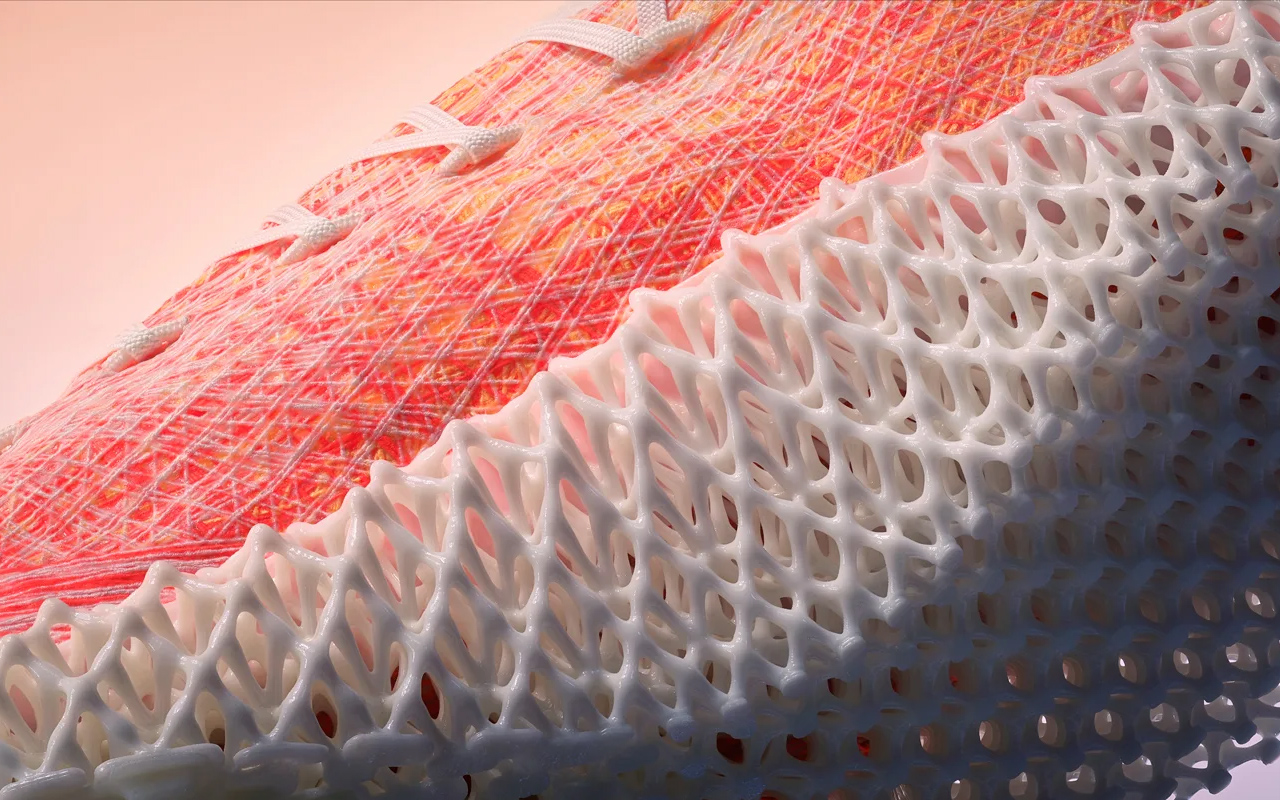

Shoe manufacturers currently place threads for the upper material either horizontally or vertically, which confines the scope of how they can be placed. With the custom robot capable of running the threads at all different angles – a new world of possibilities open. This multi-layering is done with strings that are color-coded for strength and flexibility.

The red threads run through the heel, toe-box, and midfoot regions – the major load-bearing areas – since it is the stiffer and stronger of the two colors. The more supple yellow string runs over the forefoot for additional flexibility. This weaving process adds more strength to the shoe without adding weight and reduces the amount of waste involved in shoemaking.